We provide thermosyphone and water cooling solutions for heat source and components. Our products apply on high-speed computing electronic systems. Such as servers, large computers, etc. Also, are used in projectors and CPU/GPU related products.

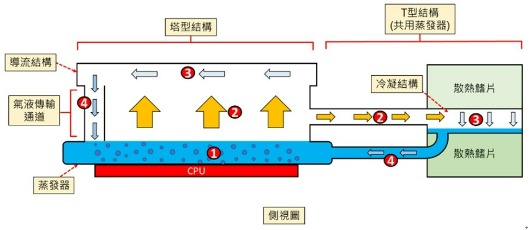

Standard Thermosyphone

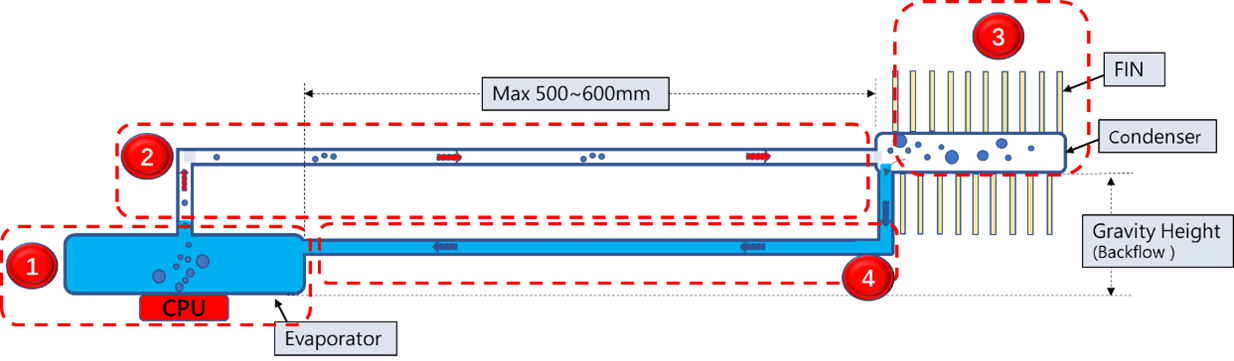

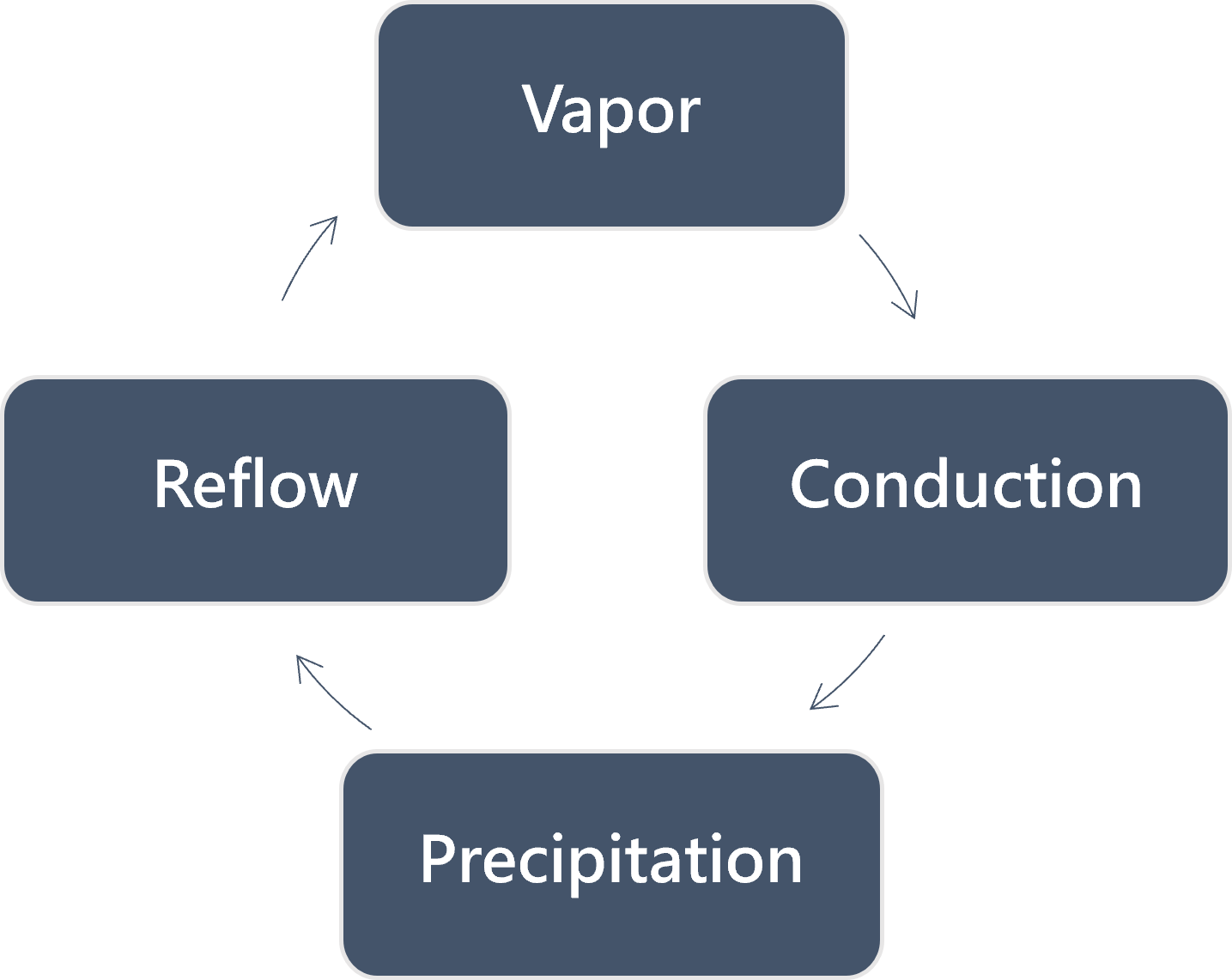

Step 1. Vapor

Evaporator (refrigerant R134a) absorbed heating of the CPU. The inside of the evaporator changes from liquid to vapor.

Step 2. Heat conduction

The vapor is transferred from the evaporator (high pressure) to the condenser (low pressure) due to the pressure difference in the pipe.

Step 3. Precipitation

The vapor is cooled by the fins, and the vapor becomes liquid after it cools and condenses.

Step 4. Reflow

By gravity, the liquid flows back from the condenser to the evaporator. It’s a loop.

To integrate evaporator and condenser in two loops. We combine three technologies:

The concept is that the liquid refrigerant absorbs the heat source of the CPU and other chips at the bottom of the heat sink and undergoes a phase change to a gaseous state.

Part of the refrigerant vapor is transferred upward to the tower for circulation and air cooling by fins.

The other part of the vapor is transferred to the front end through the piping, where it is exchanged with the cold air to condense the refrigerant into liquid form.

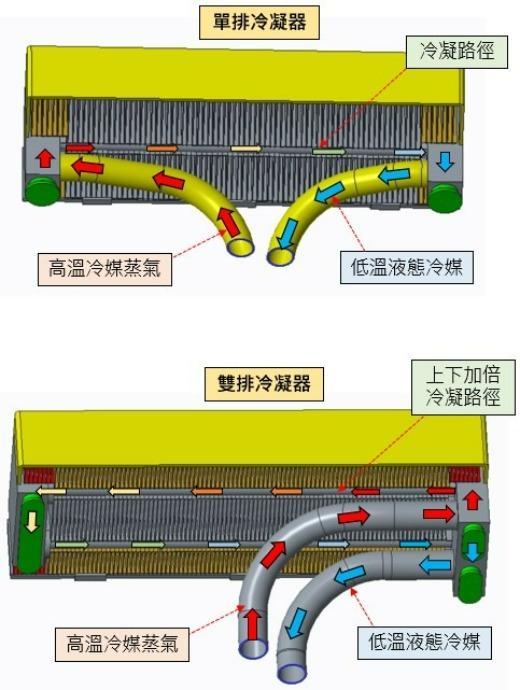

Multi-row of condenser

The concept of multi-row condenser is to create double the conduction path in the same space, so that the gaseous refrigerant can transfer more heat to the fins on the longer path, and then exchange heat with the cold air through the fins to achieve a more efficient heat dissipation function.

To browse Multi-pipe of Condenser Modules

Internal Circulation Water Cooling